Augmented reality (AR) has emerged as a groundbreaking technology with the potential to revolutionize the manufacturing industry.

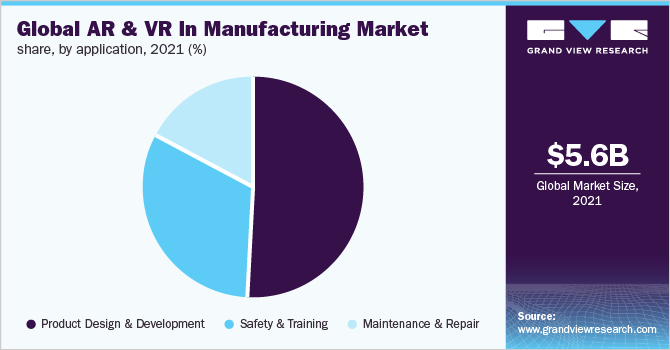

According to a market analysis report, the global augmented reality & virtual reality in manufacturing market was valued at USD 5.57 billion in 2021 and is projected to experience a compound annual growth rate (CAGR) of 29.3% from 2022 to 2030, highlighting the rapid adoption and growth of AR in this sector.

By seamlessly blending the physical and digital realms, AR enhances the way manufacturers design, produce, and operate.

In this blog, we delve into the world of augmented reality in the manufacturing industry. We explore the innovations that have emerged and the transformative impact they have had on various aspects of manufacturing operations.

Understanding Augmented Reality

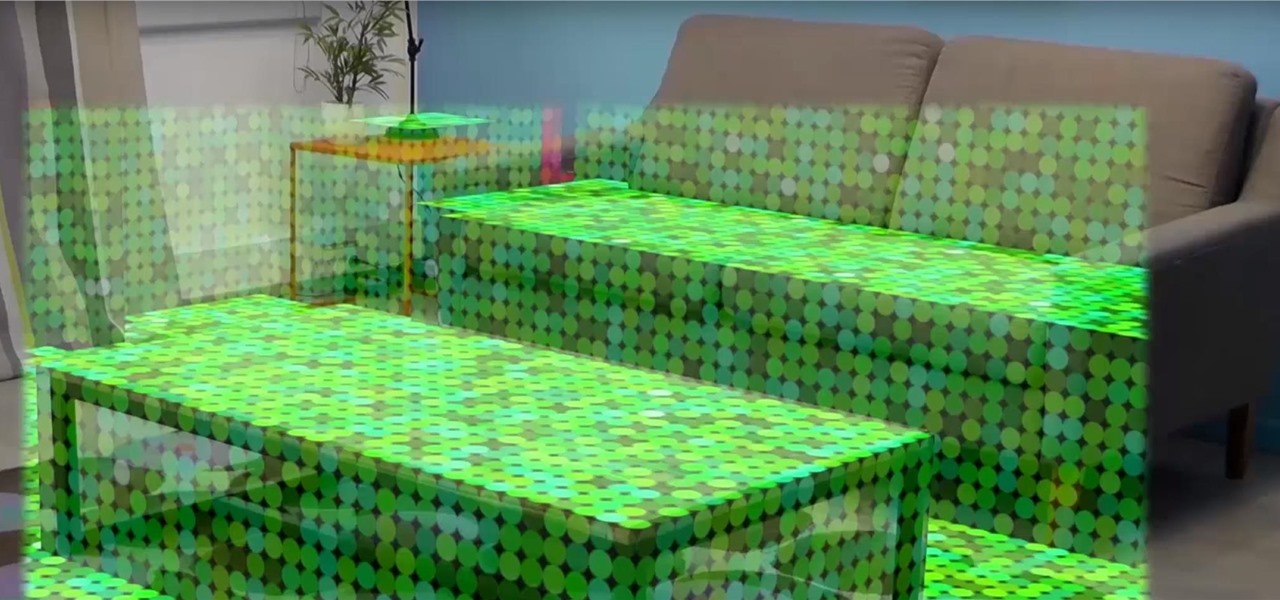

Augmented reality (AR) is a technology that enriches the real-world environment by overlaying digital content, such as images, videos, or 3D models, onto the user’s view. Read this article for a more in-depth definition of augmented reality.

Through the use of AR-enabled devices, users can seamlessly interact with both the physical and digital elements, enhancing their perception and understanding of the world around them. Scan the QR code below to test it out by yourself.

The key features of augmented reality include:

- Real-time interaction: AR provides real-time feedback and interaction by overlaying digital information onto the user’s immediate surroundings. This allows for dynamic and interactive experiences, enabling users to manipulate virtual objects or access contextual information effortlessly.

- Spatial mapping: AR utilizes advanced computer vision techniques to understand and map the physical environment accurately. By recognizing surfaces, objects, and spatial dimensions, AR systems can precisely place digital content within the user’s surroundings, ensuring seamless integration between the virtual and real worlds.

- Contextual information: AR offers contextual information by presenting relevant data, instructions, or visual cues in the user’s field of view. This information can range from step-by-step instructions for assembly tasks to real-time performance metrics or safety alerts, providing users with valuable insights and guidance.

The distinction between AR technology and virtual reality

While augmented reality and virtual reality (VR) are related technologies, they differ in their approach and purpose. Augmented reality enhances the real world by overlaying digital content onto the user’s view of real objects, whereas virtual reality creates an entirely immersive digital environment that replaces the real world.

Unlike VR, which typically requires users to wear headsets that completely immerse them in a virtual world, AR enables users to perceive and interact with the physical world while augmenting it with virtual elements.

Examples of popular AR technologies and devices used in manufacturing

The manufacturing industry has witnessed the emergence of various AR technologies; here are a few popular examples:

- AR headsets: AR headsets or ar glasses such as Microsoft HoloLens and Magic Leap, provide users with a hands-free AR experience. These wearable devices feature transparent screens that overlay digital content onto the user’s field of view, allowing for immersive AR interactions and providing real-time contextual information.

- Mobile AR applications: Mobile devices equipped with augmented reality capabilities, such as smartphones and tablets, have become valuable tools in the manufacturing industry. AR apps enable workers to visualize 3D models directly on their devices.

Innovations in AR for Manufacturing

AR-assisted assembly and production processes

Real-time digital overlays for guided assembly

AR enables workers to see real-time digital overlays on physical components during assembly. These overlays provide visual cues, highlighting the exact placement of parts, connectors, and fasteners.

By guiding workers step-by-step through the assembly process, AR minimizes errors, reduces rework, and speeds up the production line.

Curious about using our platform?

Discover the ease of creating 3D viewers with Visao’s online platform! Our new whitepaper proves just how easy it is – even for employees with no 3D experience. Don’t just take our word for it, see for yourself!

Virtual work instructions and step-by-step visual aids

AR technologies offer interactive work instructions through virtual overlays, eliminating the need for paper-based manuals or digital displays.

Workers can access comprehensive visual aids directly in their field of view, displaying each step of the assembly and production process with clear instructions, diagrams, and animations.

AR-based quality control and inspection

Visualizing defects and anomalies in real-time

AR allows inspectors to overlay digital representations of expected product features onto physical objects, enabling them to identify deviations, defects, or missing components quickly.

By highlighting discrepancies in real-time, AR enhances the accuracy and speed of the quality control process inspections, which reduces errors, leading to better product quality and reduced manufacturing defects.

Streamlining inspection workflows with AR-enabled tools

AR-based tools, such as measurement overlays and virtual gauges, enable inspectors to perform precise measurements and assessments directly on physical objects.

These tools provide real-time feedback, comparing actual measurements against specified tolerances and generating instant pass/fail indicators.

Remote collaboration and training with AR

Connecting experts and technicians virtually for remote assistance

AR facilitates real-time collaboration between experts and technicians regardless of their physical locations. Using AR-enabled devices, technicians can share live video feeds of their work environment with remote experts, allowing experts to provide remote guidance, troubleshooting, and support.

Experts can also overlay digital annotations and instructions onto the live video feed, helping technicians perform complex tasks or guide workers to resolve issues with precision and efficiency.

AR-based training simulations and on-the-job guidance

AR technology has revolutionized training processes by offering immersive and interactive simulations. Trainees can use AR glasses or mobile devices to visualize virtual objects, and scenarios overlaid onto their physical environment.

This AR-based training allows for hands-on learning experiences, where trainees can practice assembly, equipment maintenance, or troubleshooting procedures in a safe and controlled virtual environment.

Impact of AR in the Manufacturing Industry

Enhanced productivity and efficiency

The adoption of augmented reality (AR) in the manufacturing industry has had a significant impact on increased productivity, and efficiency, revolutionizing various aspects of operations and production lines.

Reducing errors and rework through guided assembly

AR-based guided assembly processes have proven to be instrumental in reducing errors and minimizing the need for rework.

By overlaying digital instructions and visual cues onto the assembly process, the AR system ensures that workers follow precise steps and correctly position components.

Accelerating training and onboarding processes

AR has transformed training and onboarding of new workers in the manufacturing industry, enabling new employees to acquire the necessary skills and knowledge quickly. The safety and training segment is expected to expand at a lucrative CAGR of 29.0% over the forecast period.

Improved safety and reduced risk

Minimizing workplace accidents through real-time safety warnings

Augmented reality can provide real-time safety warnings and alerts to workers, helping them to avoid dangerous situations. By superimposing digital information onto their field of vision, AR can detect potential hazards in the real environment, such as moving machinery or dangerous materials, and issue warnings to avoid accidents.

These visual cues and notifications serve as a constant reminder to workers, enhancing their situational awareness and reducing the likelihood of workplace incidents.

Enhancing ergonomics and reducing physical strain

AR technology can optimize ergonomics in the manufacturing environment, leading to a reduction in physical strain and injuries.

AR devices can provide workers on factory floor with personalized information on proper body mechanics and posture, ensuring they adhere to ergonomic guidelines.

Cost savings and waste reduction

Optimizing resource allocation and minimizing material waste

AR helps manufacturers optimize resource allocation by providing real-time data and visualizations. With AR overlays, workers can access critical information such as inventory levels, production targets, and material specifications.

This enables them to make informed decisions regarding resource allocation, reducing waste by ensuring materials are used efficiently.

Streamlining maintenance and repair operations

AR-enabled maintenance guidance provides technicians with real-time instructions and visualizations, guiding them through complex repair tasks with precision.

This reduces the need for manual reference materials and the time spent on troubleshooting, resulting in faster and more efficient maintenance operations.

Additionally, AR can provide access to real-time equipment data and predictive maintenance insights, allowing manufacturers to proactively address potential issues, prevent costly breakdowns, and optimize the lifespan of machinery.

Real-world examples of companies implementing AR in manufacturing

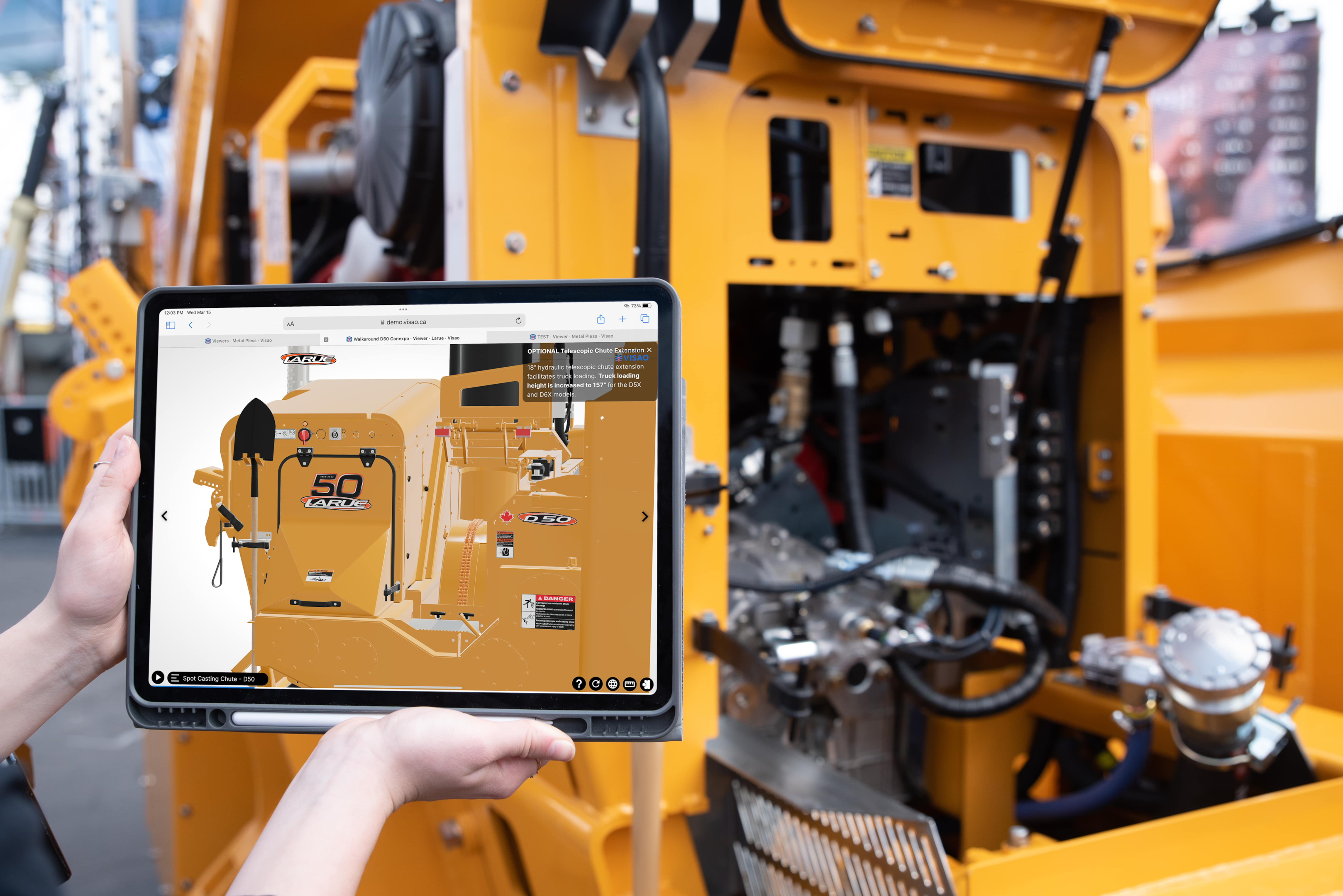

Our client, Christophe from Larue, had an exceptional experience with Visao’s 3D/ augmented reality platform.

What truly impressed Christophe was Visao’s usability and performance. Our responsive 3D specialists provided prompt guidance throughout the process of creating their 3D models, ensuring his satisfaction.

As he explored Visao further, Christophe realized the immense value it brought to Larue. According to him, Visao’s platform offered a much better return on investment compared to traditional 3D animation videos.

One of the significant advantages of using Visao, as Christophe highlighted, is the ability to make real-time changes and updates to the model. If there are any modifications in Larue’s product, such as a change in colour, it can be easily updated on the platform hosted in the cloud.

This level of flexibility and cost-saving is simply not possible with 3D animation videos, which require expensive reshoots and redistributions.

Moreover, Christophe recognized the potential of Visao to reduce costs during trade shows. Rather than transporting expensive and resource-intensive equipment, such as a snowblower, to exhibitions, Visao allows Larue to showcase their product on a tactical screen for a comprehensive and immersive experience.

Christophe particularly enjoyed the visual representation of the real-time animations and the simplicity of obtaining a 360-degree view with a realistic feel. The augmented reality function also left a lasting impression on trade show attendees, ensuring that Larue’s machine stands out and remains memorable.

Want to learn how our client brought their tradeshow experience to another level?

Challenges and Future Outlook

Technological limitations

One of the biggest challenges is software access, as highlighted by Perkins Coie’s research. AR technologies are still evolving, and manufacturers may face limitations in terms of hardware capabilities, software compatibility, and data integration. However, the encouraging news is that leading mobile devices manufacturers like Samsung and Apple have integrated augmented reality features into their devices, making this transformative technology more accessible to a wider audience.

Cost considerations

Implementing AR solutions can involve significant upfront costs, including the purchase of AR devices, software licenses, and infrastructure upgrades. The creation of a 3D model of a product by a 3D artist typically costs between $1,000 and $3,000, depending on the complexity of the product, and takes several days and weeks. The license for software hosting AR technology can cost between $100 and $2,000 per month.

Consequently, the average cost of an AR project ranges between $7,000 and $250,000, depending on the size of the required solution.

By collaborating with Visao, which specializes in AR technologies for manufacturers, the latter can access expertise and reduce the costs associated with custom development.

Workforce training and skill development

Skill development is essential for maximizing the potential of AR in the industry.

Additionally, integrating AR involves design considerations, such as reorganizing product pages, and technical challenges, such as ensuring quick and accurate loading of 3D models in the desired location.

Ongoing advancements and future possibilities for AR in manufacturing

Enhanced AR devices and wearables

AR devices, smart glasses and wearables are becoming more lightweight, ergonomic, and user-friendly, offering improved comfort and extended functionality. Advancements such as gesture recognition, eye tracking, and voice commands will further enhance the usability and practicality of AR devices. Indeed, Apple just announced they would soon release a mixed-reality headset called the Reality Pro.

Predicting the potential long-term impact of AR on the manufacturing industry

- Improved collaboration and remote work: AR enables real-time collaboration among remote teams, connecting experts and technicians virtually for troubleshooting, training, and knowledge sharing.

- Smarter factories and streamlined workflows: The augmented reality solution has the potential to integrate seamlessly into existing manufacturing workflows, enhancing productivity, reducing errors, and optimizing resource allocation.

- Personalized customer experiences: AR can enhance customer experiences by allowing them to visualize products in real-world environments, customize designs, and make informed purchasing decisions.

Conclusion

AR has the power to reshape traditional manufacturing processes, enabling greater collaboration, improved decision-making, and enhanced customer satisfaction.

The challenges associated with the implementation and adoption of new technology can be overcome through strategic planning, investment in training and upskilling, and partnerships with AR solution providers such as Visao.

Take the next step towards revolutionizing your manufacturing processes with 3D & AR by contacting Visao today. Our experts are ready to assist you in harnessing the power of augmented reality for your business’s success.